PTFE hoses are incredibly useful for a wide range of applications, from home plumbing, fire extinguishers, gas piping to specialised applications in mining, defence and other industries. These hoses are uniquely equipped to prevent fluids from leaking out and contaminating the surrounding environment.

PTFE hoses have excellent temperature characteristics both in high and low temperatures as well as excellent chemical resistance, non-contamination properties, low coefficient of friction and resists deterioration. Therefore the hose is used generally in applications where all or one of the above properties is a key requirement.

What are PTFE Hoses?

Polytetrafluoroethylene (PTFE) is an engineered fluoropolymer. Outstanding resistance to chemicals and an ability to withstand a broad temperature range of -54°C to 260°C are primary attributes that make it a useful material for hoses. It can handle the majority of fluids and ambient temperature conditions found in most industrial applications. PTFE hose can be used in aerospace, automotive, chemical, mining, defence and industrial applications.

An extremely low coefficient of friction (0.05 to 0.20) in PTFE results in a non-stick surface. Water absorption of PTFE is also negligible, less than 0.01% by ASTM test, and it is FDA-approved for food and pharmaceutical use. PTFE is chemically inert and will also withstand flexing and vibration without failure from flex fatigue. It will not break down or deteriorate in service, and it has an unlimited shelf life because properties do not change with age or exposure to weather.

Additional Benefits of PTFE Hoses

Unlike rubber, stainless steel hose with PTFE helps to prevent gas odours from permeating the hose itself. PTFE hose resists all types of fluids and chemicals, including gas, ethanol, transmission fluid, brake fluid, power steering fluid and antifreeze. Rubber doesn’t resist these fluids anywhere near as long as PTFE since these chemicals can break rubber down. If you don’t notice it, eventually the hose will start leaking. If you don’t notice a gas leak, your vehicle could catch fire, simply due to the heat in the engine compartment.

Furthermore, PTFE has higher temperature tolerances than rubber does. This means, for example, if used in an automobile and the engine overheats, you have less chance of the heat damaging the hoses. In addition to the high heat tolerance of PTFE, it has a higher pressure rating. So if any system the hose is used in generates more pressure than it normally should, there is a drastically lower chance of blowing a PTFE hose.

PTFE Hoses Considerations

With all types of hose, increased working temperatures require a reduction in maximum rated working or burst pressure. Whenever excessive flexing, vibration, thermal fluctuations or rapid pressure impulsing is in evidence, further caution should be exercised in reducing the maximum working pressure.

Contact the Stainless Steel Experts at Austfluid Link

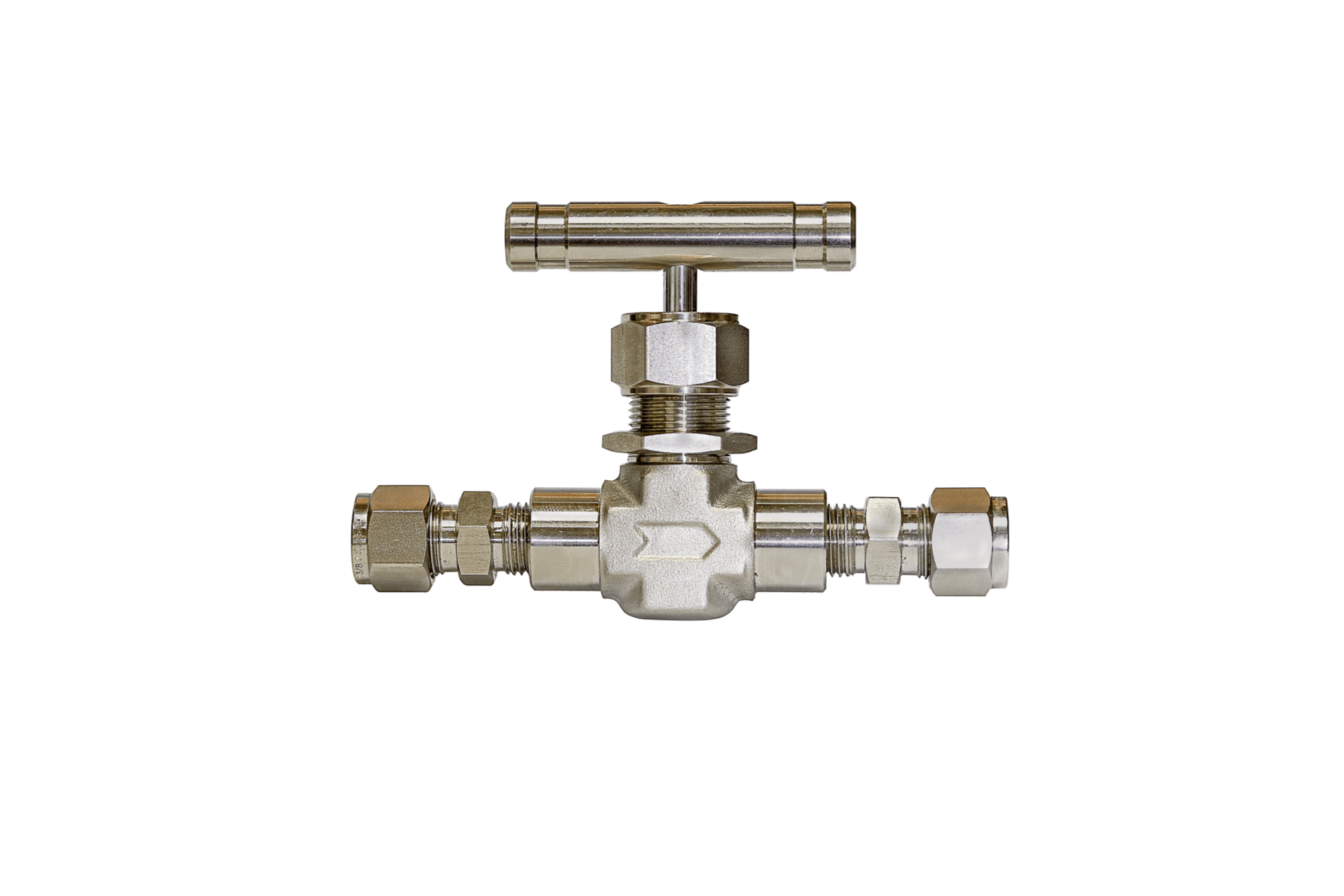

Austfluid Link is Australia’s leading supplier of stainless steel manufacturing parts including leak proof flow and control valves and high pressure hydraulic hose couplings from push-lok, 100 R6 through to R1AT/R2AT/4 wire spiral/6 wire spiral,R7/R8/PTFE hoses, with the most extensive range of adaptors in BSPP, BSPT, JIC, METRIC, ORFS, UNO thread styles to compliment the hose coupling range.

Get in touch with the team at Austfluid Link today to discuss your needs. Give us a call or contact us online.